Tech

Electrical Engineers! I just stumbled upon a connector website that you want to see.

With most of our online time spent on social media, YouTube, Wikipedia, etc. it’s easy to forget that there’s a bazillion random websites out there with people providing free useful content in the world.

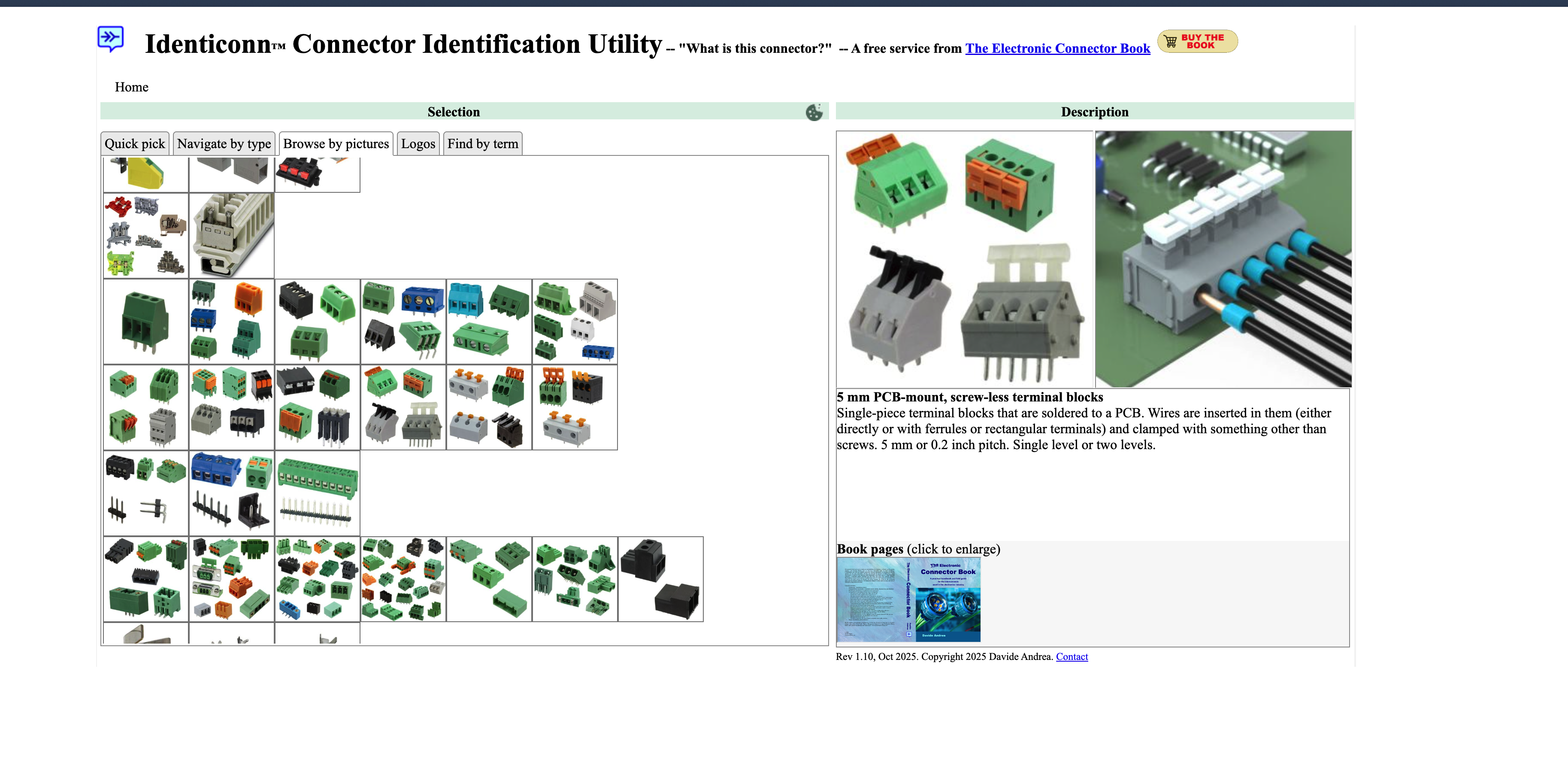

I found a link to Davide Andrea’s The Connector Book in a Reddit comment to a pertinent question. This guy catalogs electrical connectors and their uses. Have a weird connector that you don’t know what it’s used for or where to get it? Check out his connector identification guide.

#electricalengineering #ee #connectors #electronics

My Prediction on AI

Like the turn of the millennium, I think we’re in a bubble. Money is pouring in, chasing AGI. The bots are impressive, but the ROI does not meet the hype. I think we’re going to have an AI bust that will rival the Dot-com bust.

2001 came, and companies like Pets.com, GeoCities, and eToys went bankrupt. But the internet didn’t become irrelevant, right? Of course not. Trillions have been made since then on the internet. The same will happen with AI. The long game will play out big. In 10-20 years, some of the MAG 7 will be irrelevant. But there will also be a few monstrous companies that are just a couple of guys today. Just as we had a few big winners in internet search and social media, there will be a handful of big winners in the AGI space.

Put yourself in 2001 as an internet company and ask, “What would you have done?” You could have become the expert on SEO on the few platforms that survived. Or, you could have found a niche product within e-commerce and focused on it with old-fashioned business principles on profitability.

What does that look like now if we do, in fact, have a bubble that’s about to burst? Small, focused, trained ML models and narrowly integrated AI. Instead of trying to build a robot butler that washes the dishes, folds the laundry, and waters the plants, we need a pool pump that can take in sensor data and weather forecasts and automatically adjust the chemical balance preemptively to prevent algae bloom. Instead of self-driving cars, we need boats that can predict the next engine fault before you get to the lake so the dealer is ready with the part before Memorial Day weekend. Excavators that can optimize their operation to maintain total uptime.

- We’re in a bubble like the Dot-com era.

- Just as the Dot-com bust did not kill the internet, this bust will not kill AI.

- The big promises are overhyped.

- We little guys can win big by chasing the small, incremental promise

Innovate or Die?

While attending a trade show yesterday, I heard two different people say, “You have to innovate or die, right?” In the moment and in that context, I agreed with them.

This morning, scrolling the YouTubes, the algorithms knew I am planning a semi-DIY remodel and fed me this gem of a video. It featured a significantly harder-to-install outlet at 90x the cost of a regular one—for something that, to me, looks like an afterthought.

“Innovate or Die” has to be balanced with “If it ain’t broke, don’t fix it.”

In our digital world, it’s just too easy for software companies to spit out new stuff. Recently, I’ve watched my go-to apps go to crap. Photoshop, QuickBooks, and MS Office have been inundating me with in-your-face AI while also making it clear that they are training that AI on my own data. All of this is driving me to other products. I want AI to help streamline certain tasks, but don’t shove it down my throat or turn my data into your product.

“Stay in your lane, Jared. You do vehicle tech, not software. Get back on topic.”

When innovating in software, hardware, transportation, or building a better mousetrap, the goal should be improving the user experience, not just innovating to stay alive. Instead of taking two steps forward and one step back, take a minute, think, and take one smart step forward. People get all excited when you take the two steps forward but get angry when you take the one step back. If we keep taking one deliberate step forward, we should keep moving in the right direction.

If you are a customer of JARDUM and you’re asking for two steps forward while I’m pushing hard for one deliberate step forward, please understand that I’m not trying to hold you back. I’m trying to innovate where it truly improves the user experience.While attending a trade show yesterday, I heard two different people say, “You have to innovate or die, right?” In the moment and in that context, I agreed with them.

Tariffs for thee, but not for me

Last week, there was talk of 100% tariffs on semiconductor manufacturers that don’t manufacture in the US. Apple, which has been under a lot of pressure to build iPhones in the US, announced billions in investments in American manufacturing. However, they will not be assembling the iPhones in the US. They’ll be making components and shipping them to Asia where they are assembled, but this will seemingly remove the tariff requirements on their homegrown silicon.

We partner primarily with US manufacturers. All of our Jardum-designed controllers, keypads, harnesses, etc., are assembled in the US. Many of these manufacturers are privately owned, US-based, small businesses too. All good, right?

Designing electronics is complicated, and part selection is a critical part of that. You aren’t just randomly picking a processor or power FET, or doohickey that meets the spec. The engineer evaluates the quality of the documentation, the availability of application engineers and support, the responsiveness of the sales folks, stock at distributors, and lead times. Then you rigorously test the parts in the application.

Throughout this process, it’s very obfuscated where the parts are being manufactured because these are global companies. Not too long ago, we got on a call with a critical component manufacturer’s application engineer. We were both working from home and figured out we were literally in the same neighborhood. I could ride my bike to engineering facilities for NXP, Silicon Labs, ARM, and STMicro here in Austin. But these companies have fabs all over the world. I, a measly small electronics company, don’t get to dictate where they build their parts. And it’s constantly changing! We get notifications that parts move from being built in Asia to Europe or tested in Arizona but built in Asia. There are also very specialized parts that a design hinges on. If you design a power circuit based on a low-RDS smart FET, you cannot just drop in an alternative. You have to tear up the entire board.

There are times when you can guarantee a part is made in the US. Back in the part shortage times of COVID, we had two options for CAN transceivers for a design. There was a common part, but it had a 26-week lead time. Then there was a MIL-spec part built in the US with a 6-week lead time. We needed the part now, so we went with the US part. It cost 3x as much.

Apple is a trillion-dollar company that committed to building parts in the US but keeps assembling in Asia. They will not have to pay the tariffs.

Jardum, a company privately owned by a couple of dudes, will buy the best components for the application and continue partnering with US small businesses to assemble the parts. Inevitably, our prices will go up as the tariffs are applied to our COGS and many US options are more expensive from the getgo. It’s not a line item on the final assembly because the final assembly is not affected by tariffs, just the raw goods.